|

|

Production faults in cell phones – cause and effect

What breaks down in cell phones?

It would seem that when a phone breaks down – that’s it, period, nothing to ponder over. But let’s settle down for a minute and get some clarity about the definitions, and then move onto the causes of breakdowns. On the basic level there can be two types of breakdowns – critical and non-critical. By “critical” we mean all types of damage that leads to full or partial inoperativeness of the device. In other words, you won’t be able to handle it, or using it will be a real challenge, for example when the display has been rendered useless, but the handset still rings. For a common user, this division will be pretty much sufficient, for all “non-critical” issues, like paint that peels off, make the handset look lackluster, rather than hurt its main functionality. That is why it is not a rare occasion when users don’t call at service centers with non-critical defects. For instance, those casings with peeling-off paint, as the general opinion puts it, are the cases uncovered by the warranty, so the users attribute them to the way they treat their units. However, for the most part, these devices are subject to warranty repair, and the maker has to fix them and bear all the expenses.

Nevertheless, service centers can’t accept this categorization based on whether your handset works or lies breathless – they apply different classification. All problems with phones are divided up into three large sections:

- Mechanical. Everything related to spring mechanisms of clamshells and sliders, crude keypads, casings or internal components, whose replacement doesn’t require soldering (damaged display, for example).

- Electrical. Hardware-related malfunctions - resistors, capacitors, chipsets and so on. As a rule require soldering to fix.

- Software. As the name clearly puts it, all kinds of software problems fall under this category. These may include user functions (subpar menu localization, or malfunctioning alarm clock), or improper implementation or some connectivity options, resulting in abysmal call quality or rapidly discharging battery.

Technically, we can merge Mechanical and Electrical issues into the general class of Hardware malfunctions, but in order to grasp the reasons why cell phones break down, we won’t do this.

All makers, before releasing phones into the wild, test them both on their own and with the help of their major partners, operators. Obviously, detecting all possible problems with the circle of involved parties this narrow and time spans so limited is next to impossible. However, it has never been the ultimate goal – what they really aim at is getting the level of production faults all the way down to acceptable, the market average. That why the following statement is true:

100 percent of all manufactured handsets have some kind of problems when start shipping. There is no such thing as a defect-free product. There are only phones with minimum number of flaws, which are not critical for the end-user.

A cell phone that operates perfectly right out of the box is a myth. For some users this scenario is technically possible, since they don’t require a number of functions, or all they do is make calls with their handsets. But even if that’s the case, there always be a group of owners of some phone model, who will utilize many of the handset’s features in the way they are not designed/intended to be. That’s why the only thing for sure is relative quality of cell phones – there is no absolute benchmark. At the same time, the number of breakdowns and production faults is snowballing, and there are various reasons for that.

We have gathered some statistics on the abovementioned types of breakdowns on Russian market for the period of 2000-2007, and made some assumptions which way it might go in future. What we have now is truly interesting data which we would like to share.

| Year |

Mechanical marriage |

Electric marriage |

Program problems |

| 2000 |

50 |

40 |

10 |

| 2001 |

48 |

40 |

12 |

| 2002 |

46 |

39 |

15 |

| 2003 |

42 |

38 |

20 |

| 2004 |

40 |

36 |

24 |

| 2005 |

38 |

30 |

32 |

| 2006 |

37 |

27 |

36 |

| 2007 |

35 |

25 |

40 |

| 2008 |

38 |

26 |

36 |

| 2009 |

36 |

25 |

39 |

| 2010 |

33 |

21 |

46 |

On a skin-deep examination, everything looks pretty consistent. Back in early 2000, cell phones were unsophisticated software-wise, featured only a couple of functions and therefore had a small number of breakdowns caused by software malfunctions. As the phones matured in terms of functionality, the share of software-related problems increased and eventually came to dominate all others. It is important to keep in mind the fact that back then mechanical issues were quite common, for example those wearing-off wires in Motorola’s folders (Motorola v3690, Motorola v60), the same held true for some Korean devices, like those by Samsung. Also, it was seven years ago when the Samsung SGH-2400 saw release, with its casing highly exposed to wear and tear, specifically its silver paint peeled off. One of the most widely spread production faults was the display problem in the Nokia 3310 – the company was into solving this issue for quite a while, though failed to cope with the avalanche of faulty handsets. A tad earlier the market was invaded by the Ericsson R320s, sold at dumping prices, where the radio part was malfunctioning and broke down a few months into use, though it was covered by the warranty. As we go deeper into the article, we will ponder over why the maker didn’t take these phones off the line or recalled.

Hardware/software platforms and their impact upon production faults

Let’s look at the other side of the coin, the hardware department of mobile phones. In 2000 most major manufacturers switched to the concept of platform development, which shared both software and hardware aspects. In a word, they invested into creation of some all-round solution – by adding or removing a feature and altering design they got a new handset. The trait of the products back then is Series 40 from Nokia or P2K from Motorola. And the phone makers didn’t try to re-invent the wheel, by any means. For instance, in programming such approach is known as object-oriented languages, meaning that you create all libraries once and then employ them when required. Another example, if you want – panel housebuilding. Factories produce various types of panel blocks, which are then put together in a building. Fast, cheap, low expenses on modification of the house design and all this wrapped up in proven materials with known characteristics.

The phone makers picked the same way and tried to come up with platforms for which hardware-related production faults would be least possible or, at least, more predictable, and would have more to do with add-ons, rather than the core functionality. Say, when they tack Bluetooth onto a phone, it should be this module, that brings most of new malfunctions, rather than the phone part. The same goes for camera and other components.

The main goal of a manufacturer is not a crusade against any forms of production faults, but the ability to predict possible defects in future models and minimize their impact.

Naturally, it is vital to realize that nobody implements defects into devices on purpose. This is inevitable in all industries, and should be put up with, that’s the only way to go. A crucial factor in the struggle against hardware-related production faults is integration of various functions into a single chip. This means that convergent solutions automatically bring down the possibility of running to production faults, at least those that have something to do with hardware. That’s where we come across an interesting law – chunking new features and altering a hardware platform to a greater extent, for a manufacturer, means increased share of faulty units and greater budget for post-sale service. Now, an example. Why did Sony Ericsson build a hardware accelerator only in the Sony Ericsson W900i alone, and ditched it in all other models? One of the reasons was already given above – the more complicated the hardware department gets, the more defects sneak into the product. And the benefits they can extract from a stand-alone accelerator are between slim and nil, as unleashing its full potential requires substantial investments into research and development. So, a single manufacturer won’t find these activities lucrative, as they won’t be repaid – waiting for an integrated solution from a competent manufacturer, like Texas Instruments, even given its inferior specifications, yet with its being cheaper and requiring no development activities from the ground up, make more sense. The company will have to invest into implementation of such solution, development of software and so on, but cheques for these purposes will have a whole lot less digits.

The same logic holds true for the today’s market, where bundled 3D accelerators in the form of stand-alone chips are not widely adopted. By making the hardware department more sophisticated, every maker runs into increased share of defects. And as we already know, the task of every company is avoiding it. So it all comes down to striking the right balance.

Also, you should have a strong understanding that it is not only the possible risk of running into even more production faults over increased number of chipsets that influences the decision on adoption of a specific technology. Market prospects, as well as volume of potential market, ways of distribution, do matter. Here is an example we learned from the Walkman range, where phones don’t have a stand-alone DSP for sound procession, though, being the first “music-driven” handsets, rule the market. Nokia came up with its reactive for this market, which was shaped up as the Nokia N91, carrying a DSP-processor for music-only purposes. This eventually rendered the standard platform more complex and made it more expensive (both in production and servicing). They could have benefited from the economy of scale and establish a whole range of music-inclined handsets with such specifications, but this would have erased the segmentation of the company’s products and its ready-to-go solutions would’ve been less demanded. In a word, for such monumental boat as Nokia, veering round in an eye-blink is next to impossible, and the same goes for other manufacturers.

A manufacturer can come up with one product featuring unique specifications, however its production quantity will be limited, and the price- steep. Uniqueness and price are the only hurdles on the way of these products to the mass-market. Popular features are included into updates of the manufacturer’s platform, rather than presented as add-ons to other devices running on the current platform, for this increases the possibility of running into mass production faults.

“Platform” in its today’s meaning for every maker is the core, where functionality of various handsets gets tacked onto. Unique models come out as a result of deviations for the standard built into the platform, so the market charges for this correspondingly to get paid off. In a nutshell, the high margin he sets in the first place covers all expenses on fixing possible defects, unless vast majority of the units suffer from them.

The hardware issues, as time goes on, should be taking a back seat, for components are becoming time-proved, while thinning out due to integration. And this does happen, however another thing to take into account is new technologies, whose reliability at early stages might be inferior to already existing solutions. A brilliant example - metal contacts in microphones and speakers. Having replaced them with conductive rubber, manufacturers were able to save a little bit, however it was the quality that took a critical hit in the beginning. Nevertheless, shortly after that, this matter was amended, and these days most models utilize conductive rubber for contacts.

The market develops in a spiral – this way, with 2G depleted, the manufacturers have gone for 3G, which has brought about new requirements and hurdles. First of all, the software complexity has increased dramatically; what is more, new components and circuit designs provoked a boom of hardware issues. It is pretty hard to think of any relevant example, so let’s go back in 2004, when the Samsung D500 saw its release. Despite all field tests carried out prior to its launch, the Russian carrier MTS still experienced connectivity-related problems. The explanation was unearthed pretty quickly – the version of CS, PS was 0.97 within the network, whereas the handset supported 0.99. Thus the maker had to force all retailers to rectify that before placing phones onto shelves via service codes (a kind of downgrade).

The ever-growing functionality of phones frequently results in the increasing number of discrete elements, which means that the chance of defects foraying into goes up. That is why, with the advent of new networks, connectivity options or novel features the handsets get more sophisticated – this balances out the process of the components simplification and shakedown in previous models. In the long term, the software-related problems will make up to 80 percent, while all other malfunctions in sum will take the remnant 20 percent.

Examples of how vendors can save up

I always think of the complaints I heard from one of Siemens’s managers – in a word, he told me that the company churned out too reliable DECT-handsets, the Gigaset 2000 series lasted for years and there was absolutely no reason for consumers to get new units. Time changes everything, and now the manufacturer allows for different materials in new devices, which significantly cut the lifetime of handsets. If we are speaking about mobile phones, most vendors covertly take the life span of 1-2 years for granted. Take a peak in a user guide to find the life span of 3 years from the date of production, which is the longest period a handset can stay operable these days. Of course, this does not mean that after 3 years of use or being stored in a box, a handset suddenly shuts down and dies. The fact of the matter is that some materials might start falling apart in 3 years’ time – this is what the vendors are concerned about.

The never-ending quest for cost reduction, however, leads to some results that have nothing to do with financial benefits. For example, let’s examine the quality of plastic in the today’s phones. Sony Ericsson and Nokia experience enormous difficulties on this front these days. During the first year after purchase, the plastic on a Sony Ericsson branded device might crack not around the places where the casing’s details meet, but where cracks are seemingly not possible. The Sony Ericsson W850i is one of the most striking examples, by the way. Regrettably, there is no way of learning about these defects in labs, since it is only active use that can reveal such production faults.

Another weak place in Sony Ericsson handsets of late has been the joysticks. Not only do they let dust slip inside, the plastic can’t stand the friction and pressure, which makes these joysticks to fall apart literally before your eyes.

The situation with the Sony Ericsson S500i buttons had been hard to foresee - it was just recently when we learned that the green paint reacted with the adhesive used for sticking the buttons onto the casing. This way, because of the chemical reaction the base of the keys simply dissolved. At the same time, the yellow edition is free of such defects.

Nokia strives to cut its expenses on every possible front when it comes to cell phones, and sometimes this brings to life some out of the ordinary solutions. One of those is the omitted protective glass on many up-to-date models – both on sliders and folders, across all price-segments (Nokia 6131 and Nokia N95 – products for two completely different audiences). Forgoing this component enables the company to save tremendous sums of money on a twopenny-halfpenny detail and while the risk of damaging displays with some sharp object increases, it doesn’t cross the red line. To put it simply, both weaker protection of the handset and more chances to have it broken down are justified all round.

Plastic, however, is a quite different story – over the past two years the company has had a great time experimenting, trying to figure out the way to cut their costs here as well. At first, it was the peeling-off paint on L’Amour phones, where the problem manifested itself only in a year or so. The revamped range, and the Nokia 7373 in particular, got rid of the paint in a quicker fashion – within 6-7 months. A velvet pouch and careful treatment increased the chance of preserving the handset’s looks. A wee bit.

Since there was no avalanche of negative feedback on this model, the company got the green light for using similar solutions in some other handsets. Its latest offspring, the Nokia N76, gets into an obscene state in a couple of weeks (we have a separate article on this). All released units of this model are defective, which is why the company has issued a corresponding service bulletin.

It is unknown whether these experiments with plastic will go on, but the amount of feedback I receive on this issue for various Nokia-branded devices indicates that this is the problem for a lot of users. The strange thing about consumers is that they blame themselves alone for all scuffs and other types of damage the casing has suffered, saving for some outrageous examples. This means they don’t see a production fault in it – many get utterly amazed after learning about their right to get the casing replaced for free.

By saving some coins on certain components, the vendors impair conditions of servicing for the users – as a rule, all these details break down exactly at the time when the warranty expires. There is no evil intent here, only precise calculation of lifetime of the components. Power users get more “lucky”, as their units tend to break down when the handset is still covered by the warranty.

Also, I can’t overlook the example of Samsung – before the Samsung E700 the cable design in clamshells had been really simple, with all the wires being detachable the whole process of swapping them had taken several minutes and very little money. But soon enough the statistics suggested that the number of warranty claims had dropped down, so the company went for its “cost-reduction” mode - the cable was firmly soldered into both displays, which automatically meant replacement of the whole block, including steep displays, if it broke down. Today the same holds true for different Samsung-branded models, some clamshells still have the ribbon cable detachable, some – not. Regrettably, there is no explanation on how they pick cable types for the models.

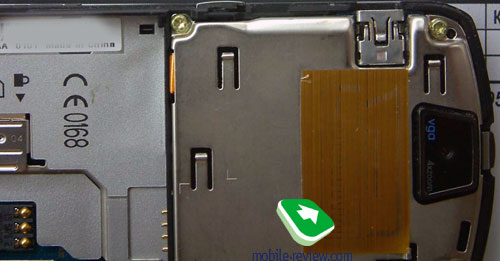

On top of all that, any new form-factor brings about new difficulties and challenges for some parts of the phone. First clamshells really suffered from the ribbon cable problems, when it worn off it was a nightmare. It took the technology a lot of time to mature, however these days, such issues mix with other hardware problems, making a relatively small share. At the same time, the today’s sliders experience a lot of difficulties with broken ribbon cables, for some models it has grown into a full-scale epidemic, specifically the Samsung D840.

It would be to wrong to believe that production costs for handset manufacturers are absolute, and the companies are willing to sacrifice quality for this. By no means. Any manufacturer always evaluates the risk of breakdowns and subsequent warranty expenses. However, no manufacturer is ready to create his solutions in a way to make them outlive the warranty period, for this inevitably results in increased product price, while not giving any substantial edge over the competition. The strategy of “durable phones” is doomed, since it reduces the target audience and boosts products’ life time. Neither manufacturers nor carriers are interested in this outcome.

What can consumers do?

Willingly or not, the manufacturers set the pace of our lives, prescribe the life span of mobile phones, which ranges from 1 to 2 years. Some models actually remain good as new even after several years, whereas some start falling apart in a few months’ time. In some cases of utterly careless treatment (like scratches left by keys etc), it is, to say the least, unwise to insist on getting the phone repaired – no service center will take on this job. But if you do treat your device with due care, warranty repair is possible and should be demanded in any event.

Terms of servicing vary by region, however you won’t find a place where makers announce defects in their solutions – you can only learn about them from other users, for example, on our forum. In fact, once a model starts shipping, it normally takes no longer than a month to reveal all widely spread productions faults. In their turn, manufacturers notify their partners of these defects via service bulletins – common users have no access to such documents.

As a rule, the retailer you bought your phone from, asks for a letter from an authorized service center stating that the problems you experience with the device stem not from the way you interact with it, but from a production fault, or malfunction of some components. That’s where the “flavor” is. Service centers prefer to repair your device, or, if there is no other way to go, buy it out from you and replace with a new unit, rather than hand you a letter confirming a production fault. If they do it, the reaction of the maker, which is the senior partner of all service centers, will be sharp – basically, issuing such letter automatically means giving a consumer a legal document, which can be used to sue the company for not recalling defective products.

Other industries bring reports on recalled notebooks, digital cameras and other devices, however the market of cell phones has never experienced similar situations. At least, there were no publicly known recalls outside carrier-driven markets, so what’s the reason?

It is easier and cheaper for any manufacturer to make its image take the blow, and continue to distribute defective models. While it will be a critical blow, it is only a temporary disaster, since the market has never seen a case when all models were liable to breakdown, except for LG and malfunctioning chips (until 2004 – defect level up to 60 percent). In other words, shipping defective models in the first place, the maker knows that its service centers can fix them, and what is more, the number of warranty claims will be smaller than the number of units sold, in some cases – substantially smaller – which allows them to save on servicing. It was the way Ericsson picked with its R320s, and Nokia with the 3310 and the today’s N76. Even the logistics schemes employed by the makers are not tweaked to support mass recalls and re- assembly or amendment of software at factories. In this case, these phones will be literally made of 24-carat gold.

So, the only way to avoid such nuisances when you have nothing left to do but take your new phone to a service center after a few days of use, is study all sources of information available to you before rushing into a shop, as well as find out what first adopters think of their new gadgets. Unfortunately, that’s all you can do today.

Eldar Murtazin (eldar@mobile-review.com)

Translated by Oleg Kononosov (oleg.kononosov@mobile-review.com)

Published — 20 August 2007

Have something to add?! Write us... eldar@mobile-review.com

|

News:

[ 31-07 16:21 ]Sir Jony Ive: Apple Isn't In It For The Money

[ 31-07 13:34 ]Video: Nokia Designer Interviews

[ 31-07 13:10 ]RIM To Layoff 3,000 More Employees

[ 30-07 20:59 ]Video: iPhone 5 Housing Shown Off

[ 30-07 19:12 ]Android Fortunes Decline In U.S.

[ 25-07 16:18 ]Why Apple Is Suing Samsung?

[ 25-07 15:53 ]A Few Choice Quotes About Apple ... By Samsung

[ 23-07 20:25 ]Russian iOS Hacker Calls It A Day

[ 23-07 17:40 ]Video: It's Still Not Out, But Galaxy Note 10.1 Gets An Ad

[ 19-07 19:10 ]Another Loss For Nokia: $1 Billion Down In Q2

[ 19-07 17:22 ]British Judge Orders Apple To Run Ads Saying Samsung Did Not Copy Them

[ 19-07 16:57 ]iPhone 5 To Feature Nano-SIM Cards

[ 18-07 14:20 ]What The iPad Could Have Looked Like ...

[ 18-07 13:25 ]App Store Hack Is Still Going Strong Despite Apple's Best Efforts

[ 13-07 12:34 ]Infographic: The (Hypothetical) Sale Of RIM

[ 13-07 11:10 ]Video: iPhone Hacker Makes In-App Purchases Free

[ 12-07 19:50 ]iPhone 5 Images Leak Again

[ 12-07 17:51 ]Android Takes 50%+ Of U.S. And Europe

[ 11-07 16:02 ]Apple Involved In 60% Of Patent Suits

[ 11-07 13:14 ]Video: Kindle Fire Gets A Jelly Bean

Subscribe

|